Non-destructive testing

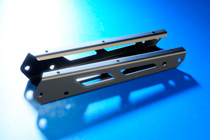

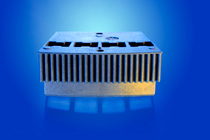

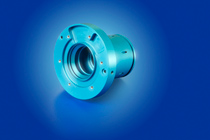

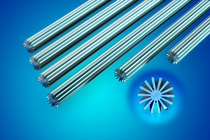

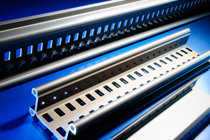

For the detection of surface defects in metals and non-porous materials, penetrant crack testing has by far been the most common method for many years. Originally, these penetrants were developed for the military and the aerospace industry. Since then, this method has been introduced in other industries for the detection of surface defects.

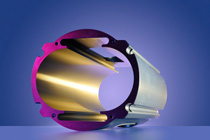

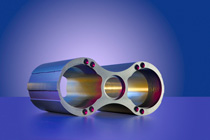

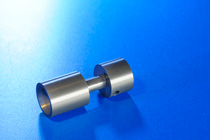

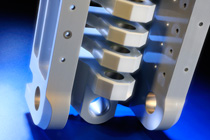

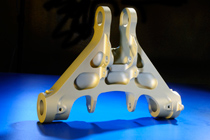

Surface Treatment mainly uses this test method on aluminium parts intended for the aerospace industry. We primarily use fluorescent penetrants. This comprises the most sensitive form of crack detection. Surface Treatment mainly uses this test method on aluminium parts intended for the aerospace industry.

"NDO"