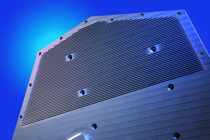

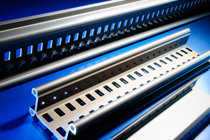

Anodising

Electrolytic oxidation, better known as anodising, is an electrochemical process in which the surface of the aluminium is converted into aluminium oxide. The resulting layer is relatively hard, inert, electrically insulating and can absorb substances. An anodised layer has an excellent adhesion, because it forms an integral part of the aluminium, in contrast to galvanised products for example. Anodising has a number of advantages.

Not only are the treated surfaces protected from chemical and mechanical influences, the resulting structure can also be used for a variety of post-treatments. Almost all aluminium alloys can be anodised. The final colour, lustre and characteristics of the oxidised layer (hardness, wear resistance, etc.) are dependent on the base material, pre-treatment, anodising parameters and thickness of the layer.

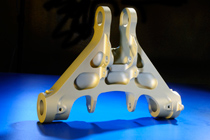

By choosing different types of electrolytes and parameters we can meet different needs. For instance, Surface Treatment has a special electrolyte for casting alloys. After anodising, any deficiencies in the casting base material will be diminished rather than accentuated. Surface sealing is performed after all the anodising processes, unless a post-treatment takes place, such as painting or adhesive application. In order to maintain optimum hardness and wear resistance, sealing of a hard anodised layer is uncommon. Hard anodising also increases the roughness of the surface. The degree of roughening is highly dependent on the aluminium alloy used.

"Medewerker Semi-technisch lab"